This blog post is for all you – mechanically inclined, problem solver folks.

If this is not your bag, you may want to skip this post.

As I sit here and write this blog, I am feeling blessed. The Mahi crew has been thru a lot in the last 3 days, but we are at piece now. Jerry & Deena went for a 20 min walk, on a hot day, to a place without Beer, Wine, Alcohol – so I stayed back to watch the boat 😃.

I had left over Pizza, a Bag of Chips, and Tequila. Look at my dinner surroundings, it is so peaceful & beautiful !

So today, one more Tequila bottle bites the dust. I think the Lucks have been dipping into my reserves.😁

So back to our last 3 days, and our current situation.

Current situation = we have been disabled for 3 days, and are waiting on a “Hynautics Check Valve” from a place in North Carolina.

Here is our story from the last 3 days.

3 days ago (Mon 16th) – Jerry is entering a lock, he throttles up to get past the swirling current at the entrance to the lock, and when he tries to come back down to idle the starboard throttle lever will not come back down to idle. Jerry puts the starboard transmission into neutral and uses one engine and steering to get us to the lock wall.

We made it thru the lock and got safely tied up on a free overnight wall, just after the lock.

We spent the night on the lock wall and discovered that one of the nylon lines going to the throttle slave assembly had a small on hole in it leaking a lot of hydraulic fluid. The line had been rubbing on a nearby bolt head. The photo cannot show the pin hole.

Luckily we had enough slack in the line to cut off 1″ of line, past the pin hole, and attach a new fitting onto the line (YES – Jerry had the spare parts).

After reviewing some of Jerry’s paperwork and doing some googling, we figured out how to bleed the system.

It was a long labor intensive process to bleed the system (1-2 hours). But we got the system bled and headed out the next day. We made it 10 miles and thru 1 lock, and then a similar event happened again. This time there were No Leaks, and the throttle slave assembly was frozen up. The throttle would not move from its elevated 1200rpm position (idle is 700rpm). So again, Captain Luck had to come into the lock on 1 engine + steering. But this time the throttle slave cylinder was completely locked up, it would not move.

Now is a good time to describe the Mahi’s throttle system. It is called a Hynautics Throttle Control System. Here are the major components –

- Resevoir , 2) Charging Block, 3) Lock Out Valve, 4) Throttle Slave Assembly

The Mahi’s throttle & transmission system is a mechanical/hydraulic system, with trade name Hynautics. It is a very old system. There are 2 Transmission levers & 2 Throttle levers. Basically, when you move one of the levers, like the Starboard Throttle, it sends hydraulic fluid down to a slave cylinder attached to the engine. The hydraulic slave cylinder then moves a rod on the engine to raise or lower the engine speed.

Here are the components of the system

- The Resevoir – this holds all the fluid for both transmission & both throttle controls. It has a sight glass to let you know how much fluid & how much air pressure is in the system.

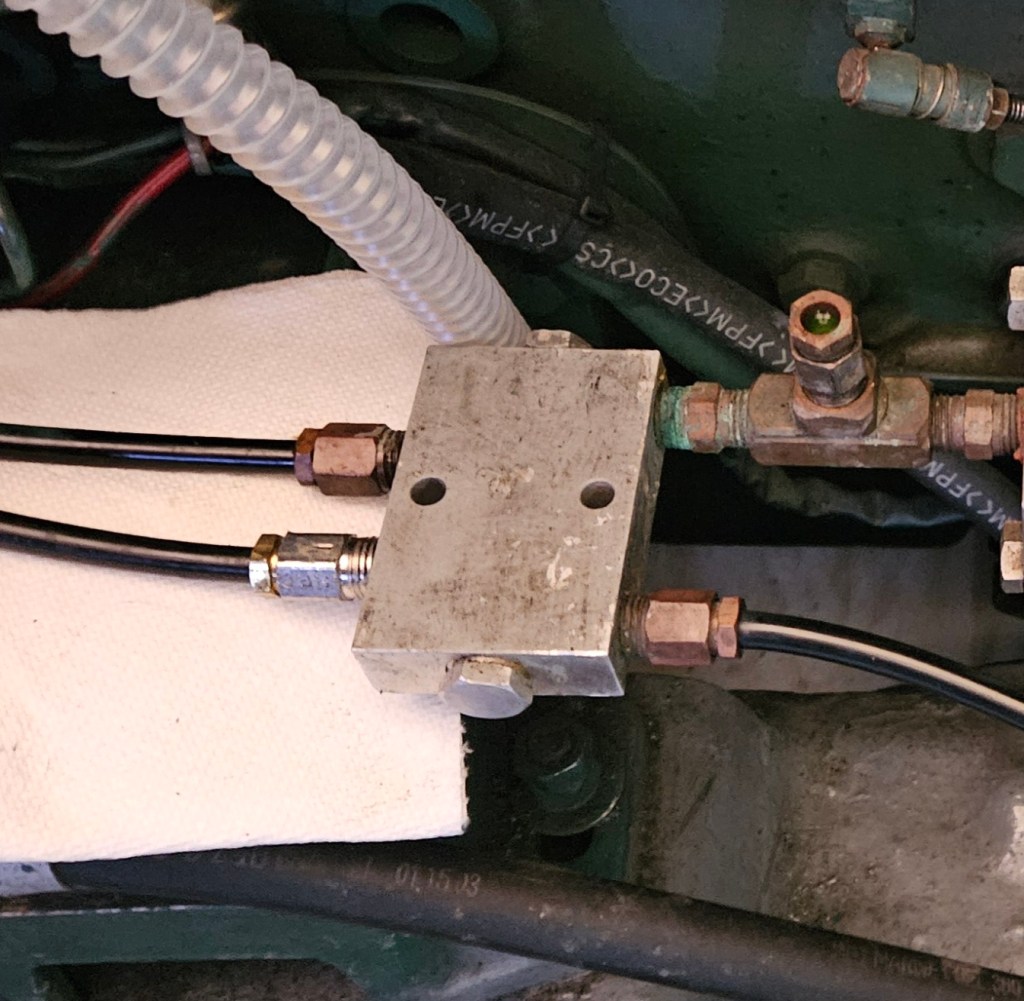

2) The Charging Block – this block distributes the fluid to the 2 Trans shift systems & 2 throttle systems. By great design – all 4 systems are separated hydraulically from each other. If one system fails, the others are not affected. There are 9 hydraulic lines going into/out of the charging block – 4 trans lines, 4 throttle lines, and 1 supply line from the fluid Resevoir. The line with my finger & the line directly across, are the 2 lines involved in our problem – the Starboard Throttle.

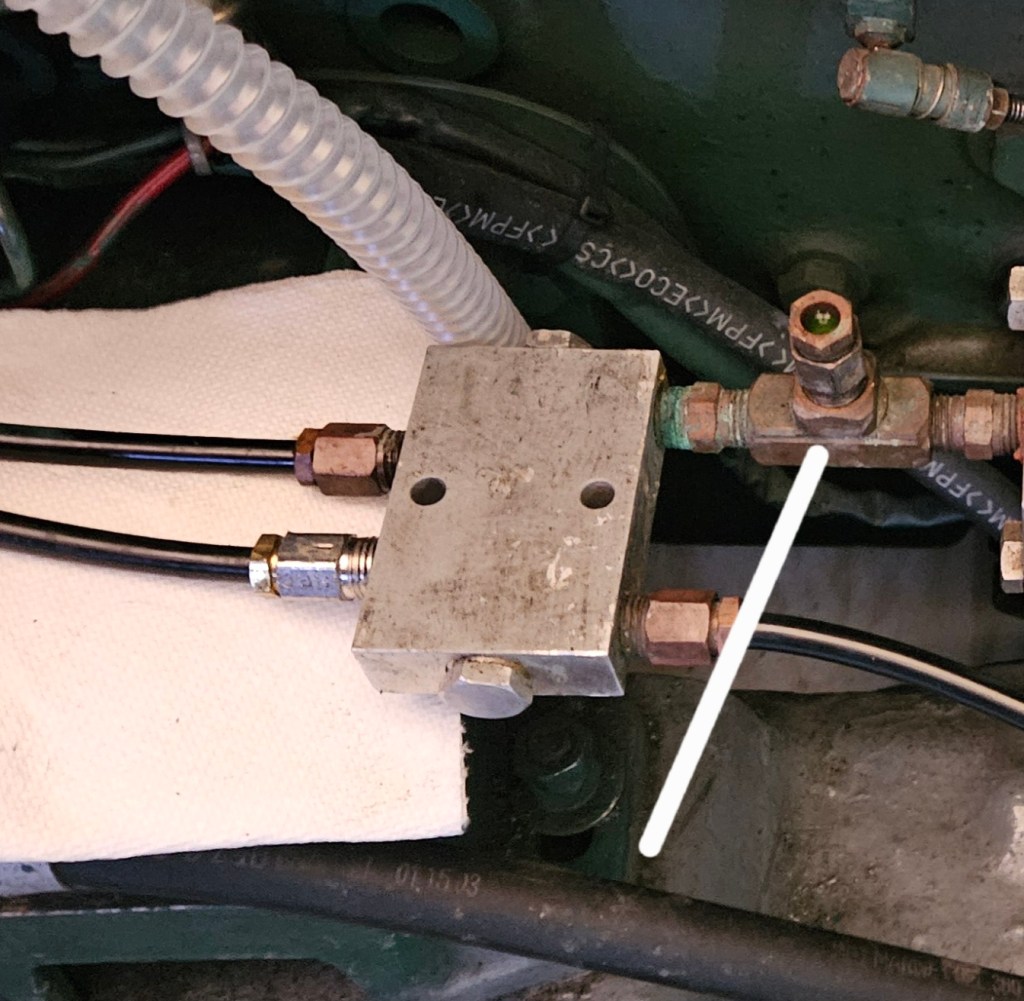

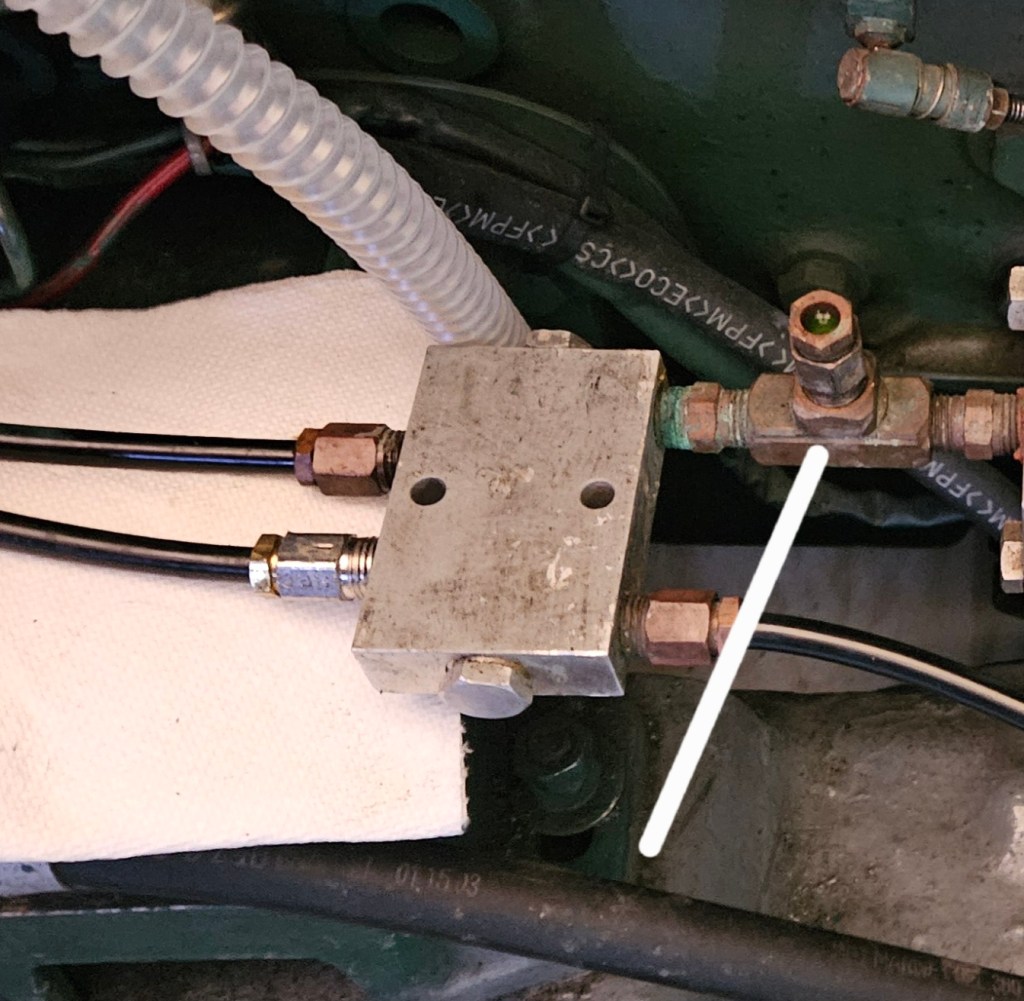

3) The Throttle Slave “Lock Out Valve” –

This is the part that Gary from Marine Systems Controls said has gone bad.

The primary function of the STV-10 is to prevent unwanted engine retardation caused by heavy-duty governor springs or vibrations. OK- I don’t really understand this either, it sounds like it is a buffer Bergen the engine and throttle control systems.

The STV-10 locks the throttle slave’s arm, allowing it to be moved only by the sender (the sender is the throttle). This means that the throttle position is held in place by the control lever at the helm and is not affected by forces like engine vibration or the opposing force of the governor springs. This valve/block helps to isolate the throttle slave assembly from external diesel engine forces, that could affect the throttle position. It helps maintain a more precise engine speed control.

This may be good when it works properly, but seems like a terrible design when it fails.

Here is what the Google search result says – ultimately, the most serious consequence of a locked STV-10 is a loss of precise control over the engine’s throttle, potentially affecting the vessel’s maneuverability and speed.

The 2 lines on the LHS are from the Charging Block & Helm, the 2 lines on the RHS go to the Throttle Slave Assembly.

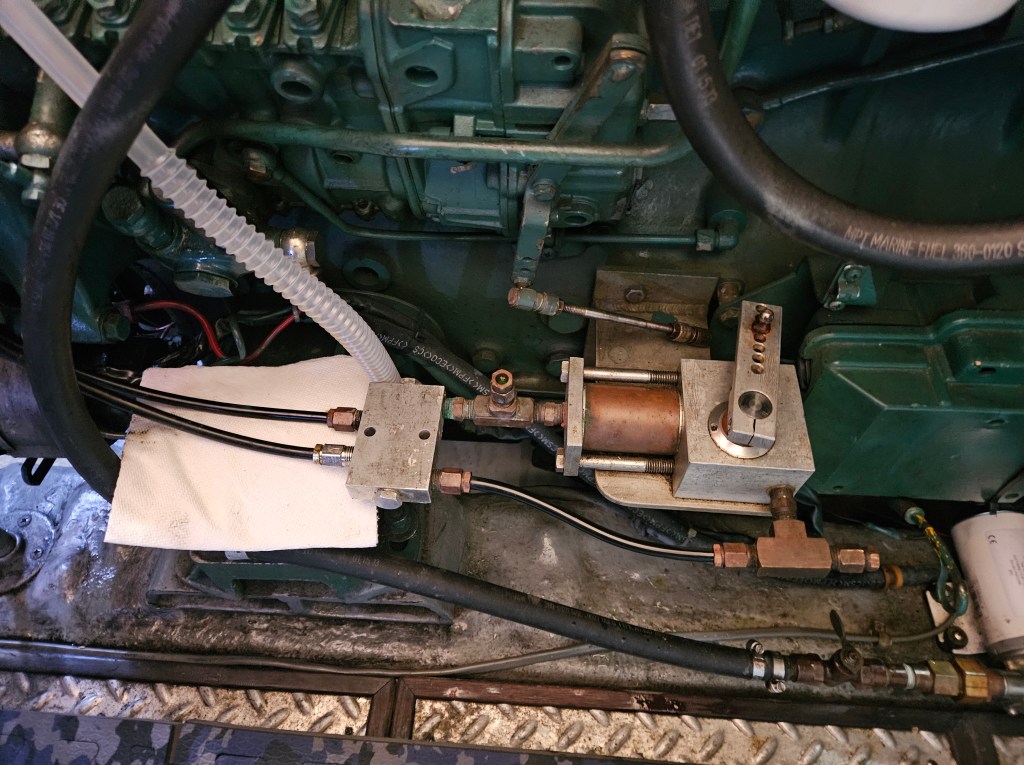

4) The Throttle Slave Assembly – this unit does all the hard work. It receives hydraulic fluid from the helm throttle lever, thru the Charging Block, then thru the Lock Out Valve, and turns the hydraulic fluid movement into a mechanical force, moving a lever that is connected to the engine throttle. Note – the throttle lever is disconnected from the Slave Assembly in this photo.

Now that we have all the components, let’s discuss our last 3 days.

Mon – 16th = we found the Slave Assembly frozen up, it would not move until we removed all the air & hydraulic pressure. And then it took a lot of force to move the throttle lever & piston.

Tue- 16th = So we thought we had an issue with the Slave Assembly. We found a company in San Diego that would rebuild the Slave for $500, but their 2 techs were on vacation until Thursday.

We found a local hydraulic guy that tried to help. He replaced the piston O-Ring & and retaining nylon Rings for $50. I thought the rings seemed loose, and the hydraulic guy agreed. Could this lock up a throttle, IDK ?

We returned back to the boat, installed the Slave with new rings, and began bleeding the system. After 1 hour of bleeding, we gave up for the night. Reminder – the original system bleeding that worked for 10 miles, also took a long time before it worked correctly.

Wed- 18th = We again tried more bleeding, and as we got further into the process, one of the 2 bleed ports began to flow really slow – OMG, what did we do !

Here is a photo of 1 of the 2 bleed ports.

So now we’re thinking “what have we done”, we have created contamination and blocked a port or valve in the system. How are we gunna find the blockage, how are we gunna clean the system without compressed air, we’re gunna have to disassemble the entire system, clean it, and bleed all over again.

After 30 minutes of panic, we settled down and began to make MORE phone calls. One of the calls that Jerry made got us to a second guy that turned out to be our savior (well 3rd place to God & JC).

Gary Thornsburg, out of North Carolina – Marine Control Systems, was the guy we needed the last 2 days. He knew everything about our Hynautics Throttle Control System.

After describing our initial problem and current status of no flow from the one bleed port, Gary told us the following –

Issue #1 – The original problem of the stuck throttle was not the Slave Assembly, it was in the Lock Out Valve. Remember that it’s purpose is to hold the throttle in position to counteract engine governor spring & vibration forces. In this case it “Locked Out” the throttle from talking to the Slave Assembly. This “lock-up” continued until we released the air & hydraulic pressure.

Issue #2 – Our lack of flow during last bleeding bleeding process was due to coagulated fluid collecting at the resevoir filter, from using an incorrect antifreeze in place of the no longer available Hynautic fluid. The other throttles and trans shifters were working due to the 100 psi pressure in the system, but potentially could have been shortly behind the starboard throttle, due to the restricted flow. Here are some photos of the Resevoir Filter & the Resevoir Tank that holds all the fluid (ok Dave Sylver, you had hinted about this). There is also a photo of the recommended replacement fluid for the Hynautic system to prevent the coagulation.

Note – this coagulation takes months or years of time to occur.

So back to The Root Cause of the throttle not being allowed to return to idle. Gary is sure, that the root cause is a bad Throttle Slave ” Lock Out Valve”. We were planning to UPS him our valve to be rebuilt, but as luck would have it – Gary had “1 NEW Lock Out Valve” left. It was more expensive than a rebuild, but to save time we ordered the new valve (from Gary), we also ordered the correct fluid (from Napa), and both items will be here tomorrow.

Gary advised us that the other 3 systems ( 2 trans shifters & the port throttle, will not have to be bled, because the Charging Valve hydraulically separates the 4 circuits.

Keep your fingers crossed for us, we should get the part & correct fluid tomorrow.

We have been blessed every step of this journey, Gary was just the most recent and currently most important blessing to be sent to us.

Oh, BTW – we have had some really cool stuff going on at this very low-key small marina.

We had a woman on a Jet Ski – DOING AMERICA’S GREAT LOOP. I had heard about her in the AGLCA forum, and today got to meet her. Look at the 4 cans of Fuel & the Chart Plotter on her jet ski.

We also have a 125ft sailboat touring the eastern half of the USA participating in the Tall Ships shows, The Liberty Clipper.

Harbormaster Frannie had told us the Liberty Clipper was coming prior to her arrival. In fact we had to move the Mahi forward to make room before the sailboat arrived. When the ship arrived, I thought that there was NoWay that she was gunna fit in the available space. The Captain did an incredible job at docking this vessel between two 40ft boats.

With only 1 engine and no thrusters. It was a very impressive docking . Look at how the forward and aft spires hang over the boat behind The Clipper, and over our Mahi in front.

That’s all for now, thanks for reading, wish us “LUCK” fixing our throttle issue and gettin back underway soon.

Mike, Deena, and Jerry 👋

Hey Murph, Brian Agar here. I know that WordPress gave me a fancy id. I did not pick it or know about it. Amazing how things can go south in a system. So glad you connected with Gary to help with situation. Eventually parts or expertise will not be available. Would you upgrade to an electronic actuator system? Thanks as always for chronicling the adventures.

LikeLike

Ah, Brian Agar !!!

Thanks again for the comments Brian.

Yes, upgrade to electronic controls makes total sense. I’m not sure if that is in the Jerry’s plans for the Mahi or not. She is an ole girl and kind of being put out to pasture at Miller Marina as a summer cottage, when we get back. Probably no more big trips for her after this one.

CU in July for that Beer we discussed

Murph

LikeLike

Way beyond my pay grade. Glad you “mechanics ” were able to get into the problem and resourcefully find a solution. Miss the travelogue aspect but understand why. Hope all works out.

LikeLike

Thanks Commander !

LikeLike

hey Mike, long time lurker of your posts. Glad you finally got problems solved , good luck on the rest of your journey

LikeLiked by 1 person

Awe thanks George. So we have never met ? How did you stumble on the blog ?

Glad you are enjoying the blog.

Mike

LikeLike